What Changes When Your Apparel Spend Hits $1M? A Supply Chain Guide

This is the strategic guide for founders and product leaders managing seven- and eight figure apparel programs. The transition from "making product" to "running a supply chain" demands new capabilities, different vendor relationships, and systematic approaches that protect profitability while enabling continued growth.

What Changes When Your Apparel Spend Hits $1M? A Supply Chain Guide

3 MINUTES

October 20, 2025

Crossing the $1 million annual apparel spend threshold is a significant milestone for any brand, but it also marks a critical inflection point. The informal, ad-hoc processes that fueled early growth become significant liabilities at this scale, and the very nature of supply chain management transforms. What was once a matter of "making product" evolves into the complex discipline of "running a supply chain." This guide provides a strategic framework for founders and product leaders navigating the complexities of seven- and eight-figure apparel programs, focusing on the core pillars of margin protection, risk management, and scalable quality control.

What Changes When Your Apparel Spend Hits $1M?

Reaching the $1 million annual apparel spend mark introduces a level of operational complexity that demands a fundamental shift in thinking. The sheer volume of production amplifies the impact of every decision, and the systems that were once sufficient become dangerously inadequate. This transformation is driven by several interconnected factors that fundamentally reshape how brands operate.

Internally, complexity multiplies as brands expand their product lines. Achieving seven-figure sales typically requires moving beyond a single category, forcing the simultaneous management of a diverse portfolio, from tees and fleece to headwear and accessories. Each category brings its own unique suppliers, lead times, and quality standards, creating a web of dependencies that must be expertly coordinated. This is compounded by the need to run multiple purchase orders in parallel, where spring delivery schedules overlap with fall development, and holiday production competes for capacity with core replenishment programs. A delay in one area can trigger a domino effect, creating a cascade of operational and financial challenges.

Externally, the landscape also shifts. To mitigate risk and optimize costs, brands must diversify their sourcing strategies across domestic, nearshore, and offshore suppliers. While strategically sound, this geographic diversification introduces a host of new variables, including different lead times, quality standards, and geopolitical risks. The consequences of these new complexities are significant. At scale, even minor inefficiencies have a major financial impact. A 2% fabric waste rate that was negligible on a 500-unit run can translate into a $20,000 annual loss at $1M+ volumes. Similarly, as a brand grows, its credibility becomes increasingly tied to its operational execution. Retailers, partners, and customers begin to judge the brand on its ability to deliver, and late shipments or quality failures can damage relationships that have taken years to build.

Protecting Margin at Scale: Beyond Unit Cost Optimization

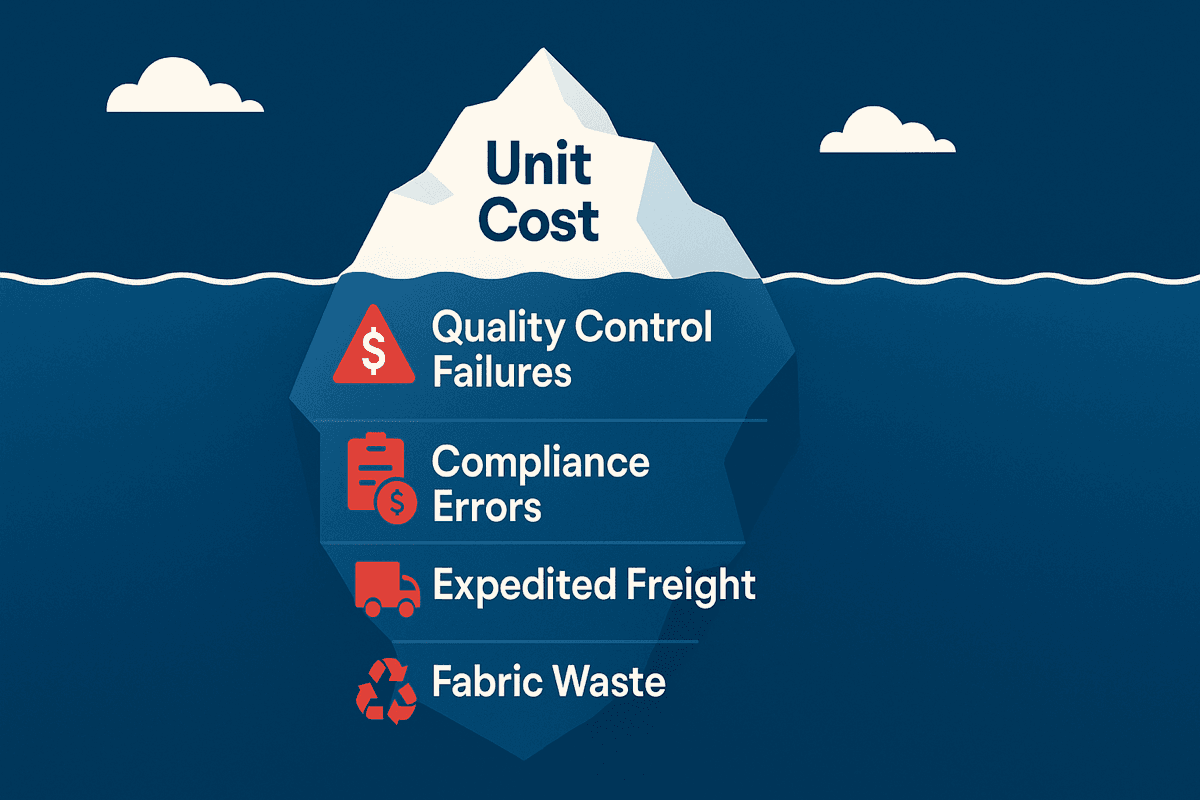

For brands operating at the $1M+ level, a myopic focus on unit cost can be a fatal mistake. True margin protection requires a holistic understanding of the total cost of ownership, which includes a variety of hidden costs that only become significant at scale. The cheapest unit price often leads to the highest total cost when factors like quality failures, delays, and compliance issues are taken into account. These costs, often invisible in the early stages, can silently erode margins and threaten the financial viability of the entire operation.

Hidden Cost | Description | Potential Impact on Margin |

|---|---|---|

Quality Control Failures & Rework | Inadequate quality control systems can lead to rework requirements that consume significant resources. | 5-15% of total production costs |

Compliance Errors & Retail Chargebacks | Failure to meet strict retailer compliance requirements can result in significant financial penalties. | 10-20% of order value |

Expedited Freight | Production delays often necessitate the use of expensive air freight to meet delivery deadlines. | 3-8% of total program costs |

Fabric Waste | Inefficient cutting and production processes can lead to excessive fabric waste. | 2-5% of total fabric costs |

Opportunity Costs | Stockouts and late deliveries can lead to lost sales and damaged customer relationships. | Difficult to quantify, but can be substantial |

To proactively protect margins, brands must adopt a strategic approach to cost management. This involves investing in fabric development to secure better pricing and exclusive access to premium materials, while also consolidating volume with key vendor partners to gain leverage in pricing, scheduling, and service levels. By working closely with a select group of trusted suppliers, brands can create a more collaborative and efficient supply chain that delivers better outcomes than transactional relationships ever could.

Furthermore, a well-managed logistics program that optimizes shipping routes, consolidates shipments, and negotiates effectively with carriers can reduce costs by 15-30%. These savings flow directly to the bottom line while simultaneously improving delivery reliability. Finally, regularly conducting efficiency audits across the supply chain can identify areas of waste and redundancy, often revealing margin enhancement opportunities of 5-10% of total program costs. These audits should become a regular part of the operational rhythm, not a one-time event.

Risk Management and Redundancy: Building an Antifragile Supply Chain

At the $1M+ level, single-factory dependence is a high-risk strategy. The failure of a single supplier can halt production, delay deliveries, and damage customer relationships in ways that can threaten the survival of the business. Concentrating 50-80% of total production capacity with a single supplier creates a catastrophic level of risk, where factory closures, labor disputes, or capacity constraints can eliminate the majority of production capability overnight. The COVID-19 pandemic provided a stark reminder of this danger, as many brands were left scrambling when their primary factories were forced to shut down.

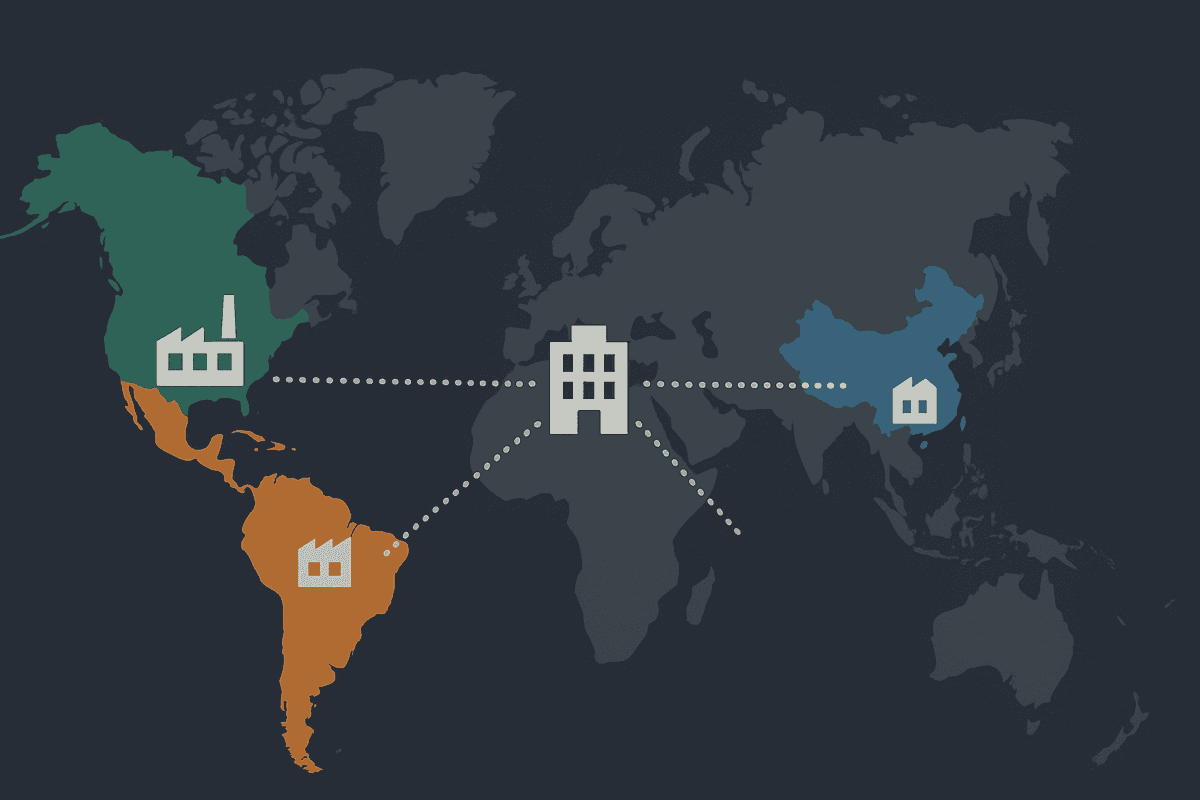

To build a resilient and antifragile supply chain, brands must embrace risk diversification and redundancy through a multi-layered approach. The first layer of defense is multi-vendor sourcing, which distributes production across several suppliers. This provides the flexibility to adjust capacity allocation based on performance and availability, while also allowing brands to leverage the unique capabilities of different partners for various product categories. This diversification requires more management overhead, but it provides essential protection against single points of failure.

The second layer is multi-region sourcing, which distributes production across different geographic areas—domestic, nearshore, and offshore. Each region offers a unique set of advantages and trade-offs that can be strategically leveraged. Domestic production provides speed, flexibility, and reduced risk, though it typically commands premium pricing. Nearshore production offers balanced cost and lead time characteristics with reduced political and logistics risk compared to offshore alternatives. Offshore production provides cost advantages for high-volume programs but requires longer lead times and carries higher risk from political, currency, and logistics factors. A brand might use offshore production for high-volume basics, nearshore for fashion-forward items with shorter lead times, and domestic for quick-turn replenishment and small-batch specialty items.

The final layer is building active redundancy by identifying and qualifying backup suppliers, maintaining a network of qualified vendors, and developing clear contingency procedures. This is not just about having a list of backup suppliers on file; it's about having a plan in place to quickly and efficiently transition production when needed. These relationships require ongoing investment and management, but they provide essential insurance against supply disruptions that could otherwise cripple the business.

Quality Control as an Enterprise System: Preventing, Not Just Detecting

As production volumes scale, the approach to quality control must evolve from a reactive, spot-checking model to a proactive, systematic one. The cost of quality failures multiplies exponentially with volume, making prevention the only viable strategy. A single failed production run can result in six- or seven-figure losses, making a robust quality control system a non-negotiable investment rather than an optional expense.

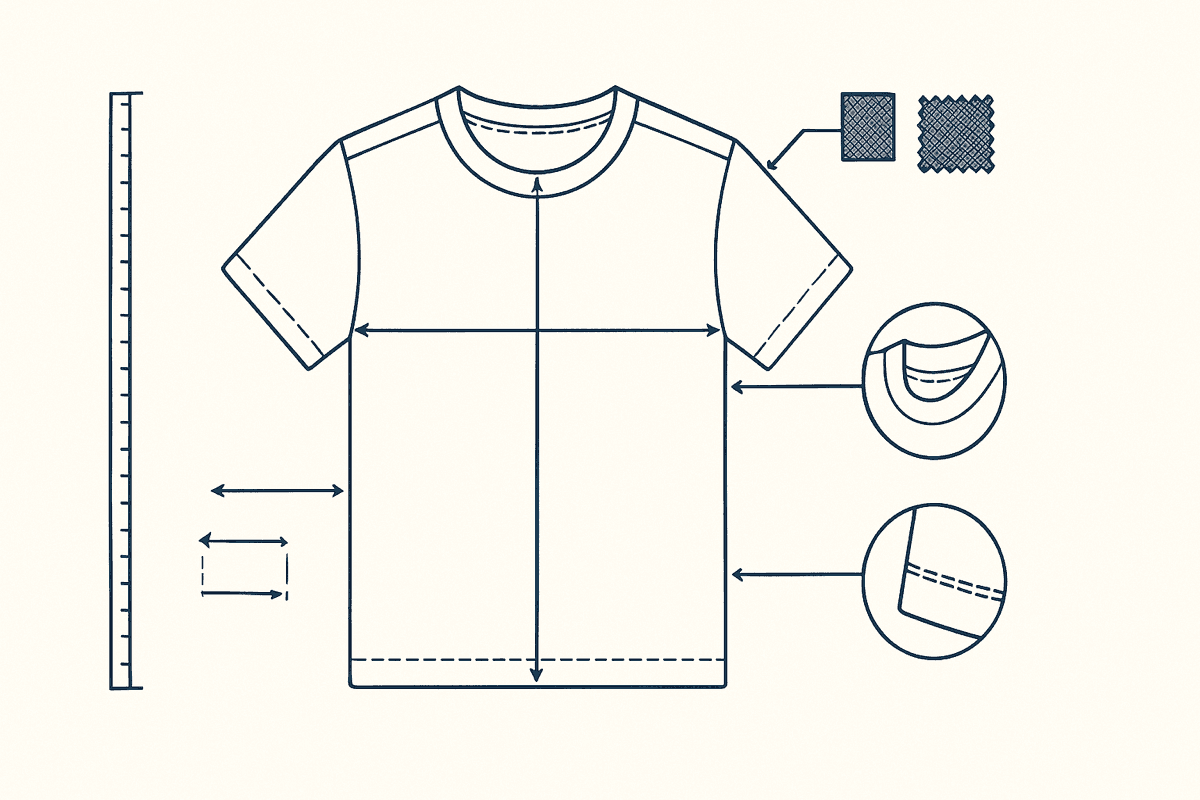

A comprehensive quality control system is built on a foundation of rigorous testing and inspection at every stage of the production process. It begins with fabric testing, where materials are checked for shrinkage, pilling, colorfastness, and stretch recovery before a single garment is cut. This prevents catastrophic failures that can affect thousands of units. For example, a fabric that shrinks more than expected can lead to an entire production run of garments that are unwearable and unsellable, resulting in complete financial loss.

The process continues with inline inspections during production, which allow for the early identification and correction of problems before they escalate. Mid-run checks verify that quality standards are maintained throughout production runs rather than just at the beginning and end, catching quality drift before it affects significant quantities. This is far more effective than waiting to inspect finished garments at the end of the line, as it allows for corrective action to be taken immediately. The final step is a carton audit, which provides a last verification that quality standards have been maintained through production and packaging, preventing defective products from ever reaching the customer. This is the last line of defense before the product ships, and it is a critical step in ensuring customer satisfaction.

This entire system is held together by clear documentation and standardization. Detailed tech packs serve as the blueprint for every garment, specifying everything from fabric and trims to construction methods and finishing details. A clear and comprehensive tech pack is essential for ensuring that the final product meets the brand's quality standards, regardless of which supplier produces it. Inspection procedures must be standardized across all suppliers and product categories to ensure every product is held to the same high standard. Finally, a robust system for tracking and reporting quality issues is essential for identifying trends, evaluating supplier performance, and making data-driven decisions to continuously improve the process. This data becomes invaluable for identifying recurring problems and focusing quality control efforts where they will have the greatest impact.

Conclusion: The Strategic Imperative

Successfully navigating the challenges of a $1M+ apparel supply chain requires a strategic and systematic approach. By focusing on the core pillars of margin protection, risk management, and scalable quality control, brands can build a resilient and profitable operation that is capable of supporting continued growth. The transition from "making product" to "running a supply chain" is a challenging one, but it is also an opportunity to build a sustainable and successful brand that can thrive in the competitive apparel industry. The brands that will succeed in the long run are those that embrace this challenge and invest in the systems, processes, and people needed to build a world-class supply chain that can scale efficiently while maintaining the quality and reliability that customers expect.

H.HARMS